The future of advanced biomanufacturing is rapidly shifting from manual, artisanal workflows to intelligent, automated systems powered by AI robotics. Multiply Labs, a leader in robotic biomanufacturing, has reached a major milestone by integrating NVIDIA’s robotics and AI infrastructure to accelerate the scalable production of cell and gene therapies—some of the most promising treatments in modern medicine.

By leveraging NVIDIA’s digital twins, foundation models, and perception AI, Multiply Labs is pioneering what it calls “Physical AI”—a new class of robotics-first manufacturing systems designed to bring consistency, traceability, and efficiency to advanced therapy production.

Solving the Scalability Challenge in Cell and Gene Therapy Manufacturing

Cell and gene therapies hold transformative potential for treating cancer, autoimmune disorders, and rare diseases. However, despite scientific breakthroughs, manufacturing these therapies remains a major bottleneck. Traditional production relies heavily on manual processes that are time-intensive, difficult to scale, and prone to variability—factors that directly affect cost, throughput, and patient access.

Multiply Labs is addressing these challenges with robotic biomanufacturing systems engineered to operate reliably in regulated GMP environments. The company’s approach focuses on automation from the ground up, enabling more predictable outcomes and improved operational efficiency.

At the core of its system are four robotic arms operating in parallel, designed to maximize output within existing cleanroom facilities. This architecture targets up to 100 times more patient doses per square foot compared to conventional manual processes—an unprecedented leap in productivity for advanced therapy manufacturing.

Integrating NVIDIA’s Physical AI and Robotics Stack

To accelerate development and de-risk deployment, Multiply Labs is integrating NVIDIA’s open robotics and AI technologies across three critical areas.

Digital Biomanufacturing Twins for Faster Development

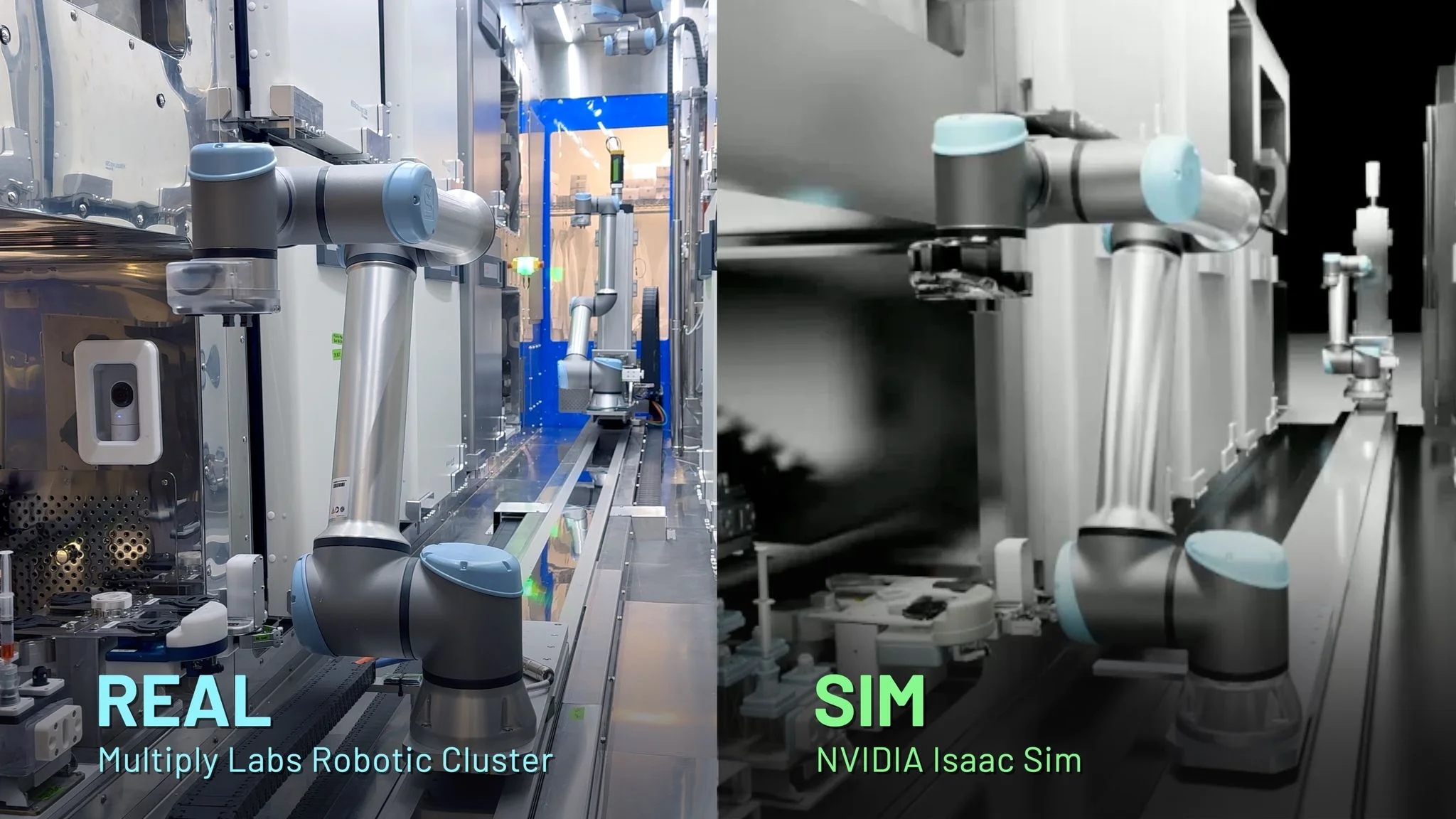

Using NVIDIA Isaac Sim, Multiply Labs is building high-fidelity digital twins of its robotic systems. These virtual environments allow engineers to simulate new hardware designs, test automation strategies, and conduct software-in-the-loop validation before any physical deployment.

This digital-first approach reduces trial-and-error on production systems, shortens development cycles, and increases confidence in system updates—key advantages in highly regulated biomanufacturing environments.

Foundation Models for Generalized Robotic Manipulation

Multiply Labs is also exploring NVIDIA Isaac GR00T, an open robot foundation model designed to learn and generalize manipulation skills. The goal is to enable robots to handle complex biomanufacturing tasks such as material handling, assembly, and adaptation to real-world variability—capabilities essential for scalable, flexible manufacturing.

Perception AI to Learn From Expert Demonstrations

To capture expert knowledge without disrupting GMP workflows, Multiply Labs is developing perception pipelines using NVIDIA FoundationPose and NVIDIA FoundationStereo. These tools enable object pose estimation, tracking, and depth perception, allowing robots to learn advanced manufacturing steps directly from expert demonstrations through non-intrusive data collection.

This approach ensures scientists can perform at their best while enabling AI-driven automation to continuously improve.

Advancing Physical AI for Real-World Patient Impact

“Advanced biomanufacturing is one of the highest value applications for robots,” said Fred Parietti, co-founder and CEO of Multiply Labs. By combining a robotics-first manufacturing philosophy with NVIDIA’s simulation, perception, and foundation model technologies, Multiply Labs is accelerating system development and unlocking new levels of scalability.

NVIDIA echoes this vision. As physical AI continues to mature, biomanufacturing represents a powerful frontier where robotics and AI can directly translate into global patient impact by improving reliability, scalability, and access to life-changing therapies.

The Road Ahead for Robotic Biomanufacturing

The collaboration between Multiply Labs and NVIDIA highlights how AI-driven robotics, digital twins, and perception systems are reshaping advanced therapy manufacturing. As demand for personalized medicine grows, scalable biomanufacturing will be essential to delivering treatments to more patients, faster and more reliably.

About Multiply Labs

Multiply Labs is a robotics company with a mission to make the world’s best robots and use them to make the world’s best personalized treatments widely available. The company develops advanced, cloud-controlled robotic systems that enable the production of advanced therapies at scale. Its customers include some of the largest global organizations in the advanced pharmaceutical manufacturing space. Multiply Labs’ expertise is at the intersection of robotics and biopharma – its team includes mechanical engineers, electrical engineers, computer scientists, software engineers and pharmaceutical scientists. The founding team got in touch because of their shared love of robots at MIT, and is now based in San Francisco, California.

www.multiplylabs.com