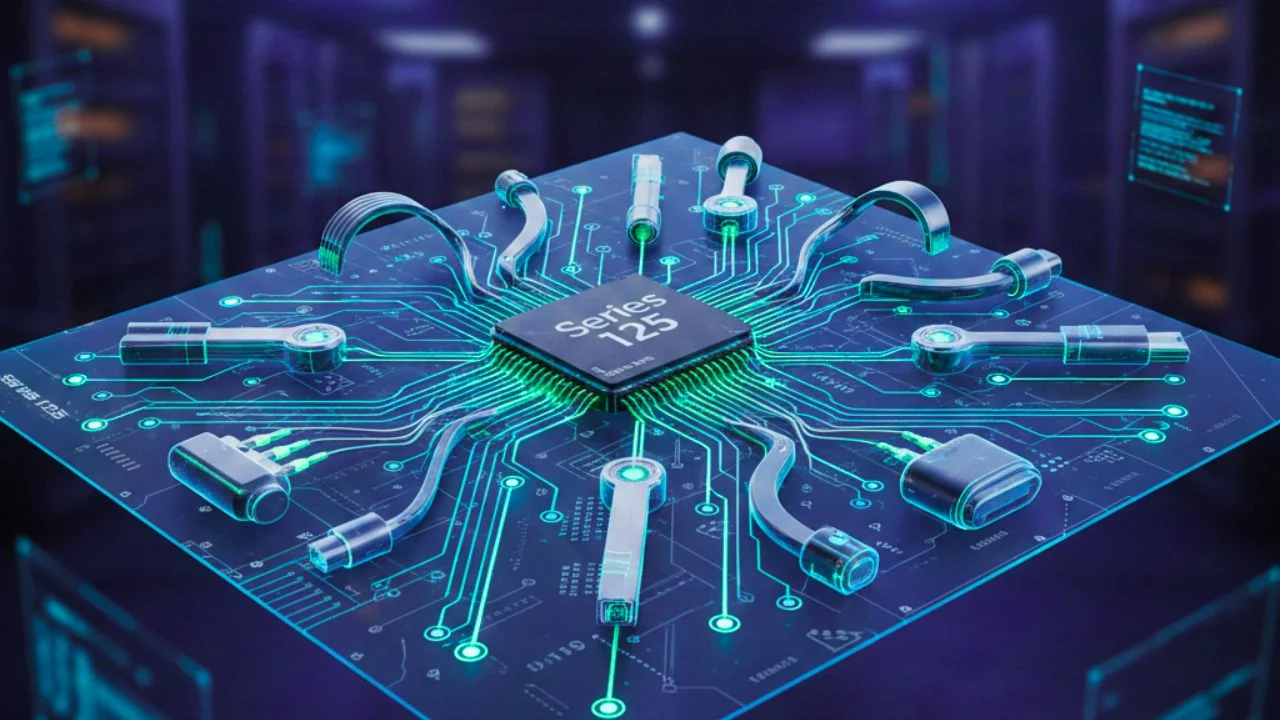

Pickering Expands Ultra-High-Density Series 125 with New Form Factors, Maximizing Channel Density for ATE Applications

Pickering Electronics, a leading manufacturer of high-performance reed relays, has expanded its ultra-high-density Series 125, renowned for offering the industry’s smallest double-pole single-throw (DPST) reed relay. This latest expansion introduces new form factors, including 1 Form A, 1 Form B, 1 Form C, and coaxial options, providing engineers with additional switching capabilities while maintaining the series’ hallmark compact design. These new variants are ideal for applications requiring maximum channel density, such as automated test equipment (ATE) switching matrices and multiplexers.

The expanded Series 125 range continues to deliver exceptional performance in a compact footprint, stacking on a 5mm x 5mm pitch. The relays feature instrumentation-grade switches that excel in mixed-signal environments, offering high insulation resistance, low contact resistance, and reliable operation. With coil options of 3V, 5V, or 12V and the ability to switch up to 1 amp and 20 watts, these relays cater to a wide range of applications, from low-level signal switching to higher-power scenarios.

“Series 125’s ultra-high-density form factor eliminates the need for engineers to compromise between performance and space,” said Robert King, Reed Relays Product Manager at Pickering Electronics. “Already recognized for offering the world’s smallest dual-pole reed relay footprint, our expanded Series 125 now includes 1 Form A, 1 Form B, 1 Form C, and coaxial options, enabling record-breaking channel density and greater routing flexibility on space-constrained PCBs.”

Versatile Switching Options for Diverse Applications

The expanded Series 125 offers three distinct switch types, each tailored to specific application needs. The first two types feature sputtered ruthenium contacts, known for their durability and reliability.

- Switch Type 1: Designed for general-purpose applications, this switch is rated at 15W, 1A (for 3V and 5V coils) or 20W, 1A (for 12V coils). It incorporates a layer of copper beneath the ruthenium contacts to dissipate heat effectively, improving current inrush handling and making it suitable for higher-power applications.

- Switch Type 2: Optimized for low-level switching, this variant is rated at 10W, 0.5A. It is ideal for cold-switching applications or scenarios involving low currents and voltages.

- Switch Type 3: Featuring rhodium contacts, this changeover switch is rated at 2W, 0.1A. Its low-power capabilities make it perfect for precision applications requiring minimal electrical interference.

Additionally, the 1 Form A coaxial options are designed for 50Ω characteristic impedance, making them suitable for switching high-frequency RF signals exceeding 1GHz. According to King, “Reed relays are the optimal solution for RF signal switching and high-speed digital signal switching. They offer a smaller footprint and faster response times than electromagnetic relays (EMR), lower insertion loss and better DC load handling than solid-state relays (SSR), and superior hot-switching performance compared to MEMS switches.”

Advanced Features for High-Density Applications

One of the standout features of the Series 125 is its effective magnetic shielding, achieved through the use of mu-metal. Known for its high permeability and low magnetic remanence, mu-metal eliminates issues caused by magnetic interaction between closely packed relays. Without proper shielding, magnetic interference could increase the voltage required to operate adjacent relays by up to 40%. In contrast, Series 125 relays achieve interaction levels of just 1%, ensuring seamless operation even in densely packed configurations.

“Full mu-metal magnetic screening enables side-by-side packing without the risk of magnetic interference,” explained King. “This allows up to 288 Series 125 relays to be placed on a PXI BRIC matrix daughter card, facilitating very high-density switching applications and saving significant cost and space.”

Additional Design Enhancements

To further enhance performance and reliability, Series 125 relays incorporate an internal diode to prevent voltage spikes caused by inductive kickback when the relay coil is de-energized. This diode provides a safe path for current dissipation, reducing electrical noise and protecting sensitive components from potential damage.

Pickering also offers a range of customizable build options to meet specific customer requirements. These include unique pin configurations, non-standard coil voltages or resistances, tailored operate/de-operate times, pulse capability, and special life testing under defined load conditions. Such flexibility ensures that Series 125 relays can be optimized for virtually any application.

Built on Decades of Expertise

Pickering Electronics’ reputation for innovation in reed relay technology is rooted in decades of manufacturing excellence. All Series 125 relays utilize instrumentation-grade reed switches, ensuring stable and long-life operation—up to billions of cycles. The company’s patented SoftCenter™ technology enhances mechanical robustness, while formerless coil construction minimizes size without compromising performance. Every relay undergoes rigorous 100% testing, including dynamic contact wave-shape analysis, to guarantee consistent quality and reliability.

Mu-metal screening not only enables high packing densities but also minimizes magnetic interference, setting Series 125 apart from competitors. Engineers can confidently integrate these relays into their designs, knowing they will perform reliably in even the most demanding environments.

About Pickering Electronics

Pickering Electronics was formed over 50 years ago to design and manufacture high quality reed relays, intended principally for use in instrumentation and test equipment. Today, Pickering’s single-in-line (SIL/SIP) range is by far the most developed in the relay industry, with devices 25% the size of many competitors. These small SIL/SIP reed relays are sold in high volumes to large ATE (automated test equipment) and semiconductor companies throughout the world.

The privately-owned Pickering Group comprises three electronics manufacturers: reed relay company, Pickering Electronics; Pickering Interfaces, designers and manufacturers of modular signal switching and simulation products; and Pickering Connect, which designs and manufactures cables and connectors.