Machine Learning Platform Analyzes Telemetry and Service History to Flag Component Replacements Before Downtime Occurs

Industrial robots deliver ROI when they operate continuously. Unplanned downtime—whether from component failure, software issues, or maintenance delays—erodes the business case for automation investments, particularly in warehouses, manufacturing facilities, and service environments operating on thin margins. Roboworx, the leading robot field service organization, today launched AI-powered predictive analytics capabilities for its Robot Service Manager (RSM) software platform, enabling the company to anticipate mechanical failures before they occur by analyzing historical service data and real-time telemetry. The upgrade shifts robot maintenance from reactive break-fix responses to proactive component replacement strategies based on usage patterns, wear indicators, and model-specific failure modes.

The new RSM AI uses machine learning to combine service history with odometry data—cycles completed, miles traveled for autonomous mobile robots (AMRs), units produced—to identify when specific components approach end-of-life conditions. This allows Roboworx technicians to arrive on-site with the correct replacement parts before failures disable robots, reducing both downtime duration and the operational disruption caused by unexpected outages.

Why Break-Fix Models Don’t Scale for Autonomous Robot Fleets

Traditional industrial equipment maintenance follows scheduled preventive maintenance intervals or reactive break-fix responses. Scheduled maintenance works when equipment operates in controlled environments with predictable usage patterns, but autonomous robots encounter variable conditions—floor surfaces, payload weights, operating hours—that accelerate wear unpredictably. Break-fix maintenance minimizes scheduled downtime but creates operational chaos when critical robots fail during peak demand periods.

This tension intensifies as organizations scale from pilot deployments of 5-10 robots to production fleets of 50-100+ units across multiple facilities. A single AMR failure in a small pilot causes minor inconvenience; the same failure in a production warehouse during holiday fulfillment season cascades into order delays, labor reallocation, and customer service issues. Traditional maintenance approaches can’t anticipate which specific robot in a fleet will fail next based on its unique usage history and operating conditions.

“With predictive analytics, we can now flag specific components for replacement based on usage levels across different models,” said Jeff Pittelkow, Managing Director at Roboworx. “When a technician heads to a site, the system tells them exactly what is likely to fail next. This enables us to anticipate issues instead of just reacting to them, which in turn helps keep the robots working at peak efficiency no matter the task.”

Key Insights at a Glance

- Predictive capability: Machine learning analyzes service history plus odometry data (cycles, miles, units produced) to identify component wear patterns and flag replacements before failure

- Performance gains: Break-fix calls reduced by up to 93% when used for preventative maintenance; repair times shortened by up to 50% through better technician preparation

- Data translation: AI-powered summaries convert technical checklists into plain-language reports for facility managers while providing technicians with complete service history and recurring issues

- Platform maturity: Five years of training data across warehouse, cleaning, delivery, and food service robot deployments inform predictive models

- Pricing model: RSM included at no additional charge for all Roboworx partners (robot OEMs and end-users)

From Data Fatigue to Actionable Intelligence

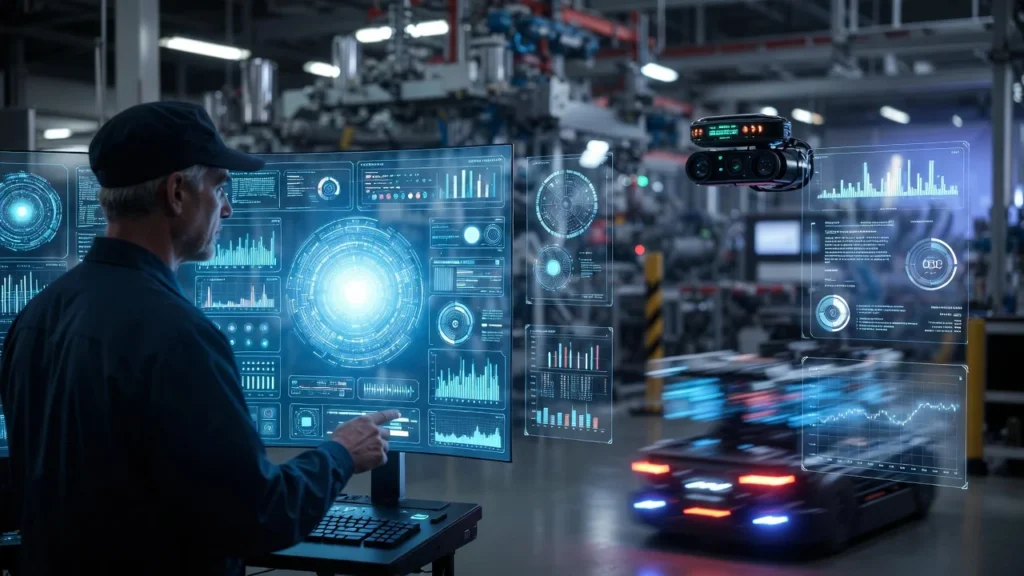

Field service organizations generate massive volumes of technical data—maintenance logs, error codes, sensor readings, work order histories—that overwhelm facility managers who need operational insights, not raw telemetry. Roboworx addresses this with AI-generated summaries that translate technical forms into concise, plain-language reports accessible through client portals, similar to a doctor’s after-visit summary.

This dual-interface approach serves different stakeholder needs. Facility managers view robot “health” status and maintenance recommendations without interpreting sensor data or error codes. Technicians access complete service history, including model-specific recurring issues and failure patterns, before arriving on-site. This information asymmetry—giving each user the level of detail appropriate to their role—reduces communication overhead while improving decision quality.

The data fatigue problem isn’t unique to robotics; it affects any field service operation managing complex equipment across distributed locations. Organizations struggle to balance comprehensive documentation (required for warranty claims, regulatory compliance, quality control) with usable information (what facility managers need to make operational decisions). Point solutions that capture data thoroughly often fail at surfacing actionable insights; reporting tools that simplify information may lack the technical depth specialists require.

RSM AI attempts to solve both simultaneously by maintaining complete technical records while generating role-specific views automatically. Whether this works at scale depends on how accurately the AI interprets technician inputs and whether the plain-language summaries actually convey the nuance facility managers need for decision-making—questions the announcement doesn’t address but production deployments will answer.

Training Data as Competitive Moat

Roboworx emphasizes that RSM has been in development for five years, accumulating service data across warehouse AMRs, cleaning robots, delivery robots, and food service automation. This training period matters because predictive maintenance accuracy depends on understanding failure modes specific to robot models, application environments, and usage patterns—knowledge that can’t be synthesized from generic robotics data or transferred directly from other industries.

A warehouse AMR’s drive motor fails differently than a floor-cleaning robot’s brush motor. Payload stress patterns in food service delivery differ from package transport in logistics facilities. Accumulated service history across these varied deployments enables RSM AI to build model-specific and application-specific failure prediction models rather than generic maintenance schedules.

This domain-specific training data represents a competitive advantage that’s difficult to replicate quickly. New entrants to robot field service can hire technicians and purchase diagnostic tools, but they can’t accelerate the accumulation of historical failure data showing how specific components wear under real-world operating conditions across thousands of robots.

“As robotic technology grows more complex, RSM AI has already proven to be an invaluable tool to ensure our experts deliver the most effective care before clients even know they need it,” said Chris McNelis, VP of Operations at Roboworx. “Technicians don’t have to change how they work because the AI handles the reporting, allowing them to focus on the hardware while keeping the client fully informed.”

Inclusion Model and Market Positioning

Roboworx’s decision to include RSM at no additional charge for all partners—both robot OEMs and end-users—positions the software as a value-added service differentiator rather than a standalone revenue stream. This pricing strategy makes sense if the primary business model centers on field service revenue, where improved technician efficiency, reduced emergency calls, and higher customer satisfaction justify absorbing software costs.

The 93% reduction in break-fix calls and 50% shorter repair times (when RSM is used for preventative maintenance) suggest substantial operational efficiency gains. If these metrics hold across the customer base, Roboworx can handle more robots per technician while maintaining service quality—improving unit economics even without charging separately for the software.

The platform’s unified view of preventative maintenance, break-fix events, and service history addresses another pain point: fragmented record-keeping across multiple systems, technician notes, and client communications. Organizations scaling robot deployments struggle to maintain consistent documentation when service records exist in email threads, spreadsheets, and disparate maintenance management systems.

Whether predictive analytics fulfills its promise depends on specifics the announcement doesn’t quantify: prediction accuracy (how often flagged components actually fail versus false positives), lead time (how far in advance failures are predicted), and failure coverage (percentage of actual failures the system anticipates versus unanticipated breakdowns). These metrics determine whether RSM AI meaningfully shifts maintenance from reactive to preventative or simply adds another data layer to existing workflows. Five years of training data and customer adoption across multiple industries suggest Roboworx has moved beyond proof-of-concept, but the ultimate test is whether robot uptime and total cost of ownership improve measurably in production environments.

About Roboworx

Roboworx offers world-class robot service, maintenance, and management, delivered by expert technicians, to ensure that both robot OEMs and end customers maximize the value of their robot fleets. Roboworx’s comprehensive services include preventative maintenance, on-call break/fix, installation, customer training & re-training, and warehousing/depot services. The company caters to a wide variety of robots across numerous industries, including warehousing, cleaning, delivery, security, and more. Roboworx’ services are available through flexible subscription or pay-as-you-go programs, tailored to meet the unique needs of each partnership. For more information, visit http://www.roboworx.io