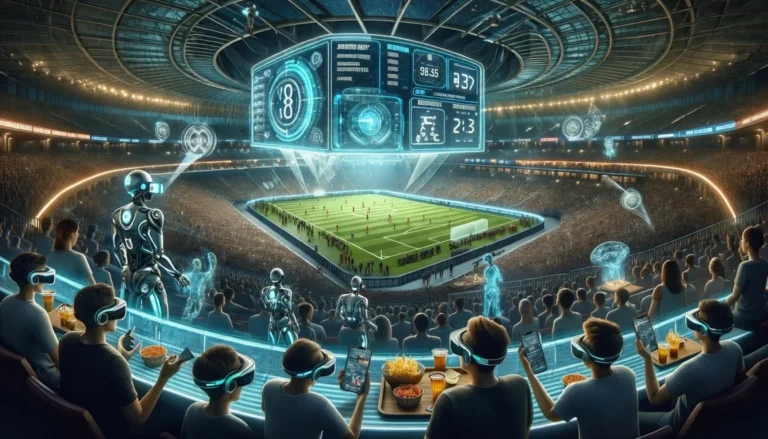

Yield Engineering Systems a recognized leader in advanced process equipment for the semiconductor industry, announced that it has secured a significant multi-tool order from a global pioneer in AI infrastructure solutions. This major customer win reflects both accelerating market demand for high-performance data center technologies and the industry’s ongoing transition toward panel-level manufacturing on glass substrates. The equipment ordered will be deployed in next-generation manufacturing lines designed to support high-throughput packaging essential for hyperscale artificial intelligence (AI) and high-performance computing (HPC) applications.

With the proliferation of AI workloads — spanning model training, inference acceleration, data movement, networking, and co-packaged optical integration — semiconductor packaging must evolve to handle drastically increased performance density and thermal complexity. To meet these needs, leading device manufacturers are adopting larger panel substrates and moving from traditional silicon interposers to advanced glass-based solutions that offer improved dimensional stability, superior electrical insulation, and tighter process tolerances. YES’s portfolio of precision Dry and Wet process equipment plays a critical role in enabling such advanced panel-level manufacturing (PLM) flows.

The order covers a wide range of YES’s flagship platforms, each engineered to support critical steps in the packaging process:

- VertaCure™ — a fully automated vacuum curing system optimized for consistent solvent removal and defect-free polymer hardening. By delivering uniform temperature distribution and exceptional particle control, it helps ensure better package reliability and higher device yield at production scale.

- VertaPrime™ — a low-vacuum vapor deposition system designed to enhance surface adhesion and prepare substrates for subsequent metallization and coating steps. The platform provides a highly controlled interface layer that strengthens bonding performance for large-panel assemblies.

- VeroFlex™ FAR — a precision panel-level reflow tool that enables uniform heat ramping and controlled interconnect formation. The system is tailored for advanced interconnection architectures that are increasingly required to support ultra-fast signal transmission between compute tiles, memory stacks, and optical modules.

- TersOra™ — an advanced edge-zone removal system that ensures clean and accurately defined panel edges, preventing chipping or contamination that could compromise the overall package structure and electrical integrity.

- SURE™ Wet Process Platform — a high-performance wet cleaning and etch solution specifically designed for large-format substrates. It provides efficient material removal and residue control to support repeatable, defect-free PLM builds.

By delivering its complete suite of integrated equipment, YES is enabling its customer to ramp a robust and scalable manufacturing strategy that addresses next-generation compute requirements. These tools are expected to serve as core infrastructure for assembly lines dedicated to some of the most demanding workloads in the technology ecosystem.

“We are excited to provide a comprehensive offering of glass-panel tools that directly support the semiconductor industry’s transition toward high-throughput panel-level packaging for AI and HPC,” said Rezwan Lateef, President of YES. “Our systems are already running successfully in high-volume production lines at several of the world’s top integrated device manufacturers and foundries. As the market moves to even larger substrates and embraces co-packaged optics, YES is uniquely positioned to support customers across both wafer-based and panel-based environments.”

YC Wong, Vice President of Sales and Business Development at YES Singapore, emphasized the strategic importance of glass substrates in future packaging roadmaps. “Glass is rapidly emerging as the substrate of choice for advanced 2.5D and 3D architectures due to its mechanical rigidity, thermal characteristics, and electrical performance advantages,” Wong explained. “Our strong regional presence in Asia and our extensive experience in volume deployment allow us to partner closely with customers as they scale their production capacity from wafers to panels.”

This latest order reinforces YES’s growing influence in the advanced packaging domain and highlights its role in solving some of the most critical challenges facing the semiconductor ecosystem — including precise curing, improved cleaning efficiency, controlled thermal processing, and reliable deposition technologies. As AI infrastructure continues its rapid expansion and the industry pushes the limits of chiplet integration, power delivery, and optical connectivity, YES remains at the forefront of enabling high-volume manufacturing platforms that can sustain the next generation of compute innovation.

With this milestone, YES continues to demonstrate its commitment to partnering with customers worldwide to drive major technology inflections that will shape the future of semiconductor packaging — from data centers and hyperscale AI clusters to emerging computing applications requiring unprecedented levels of speed, efficiency, and integration.